Boosting Productivity in Industries: Shrewd Strategies Proven Successful

Improving Industrial Efficiency: A Comprehensive Approach

In the realm of industry, efficiency is the key to success. A well-oiled machine, quite literally, can mean the difference between profit and loss. Here's how various strategies can help enhance efficiency in industrial settings.

Boosting Productivity and Reviewing Workflows

Adopting structured process improvement frameworks such as Lean, Six Sigma, Kaizen, TQM, and PDCA can help streamline workflows, eliminate waste, and align teams around measurable goals. Regular analysis of operational areas can pinpoint bottlenecks or cost drivers, allowing for the redesign of workflows to optimize material and information movement.

Using Automation

Automation can be a game-changer in industry. By automating repetitive manual tasks like material handling, assembly operations, quality control, and maintenance scheduling, labor costs can be reduced, human error minimized, and speed and precision increased. High-volume, repetitive tasks that offer quick returns on investment are ideal starting points for automation.

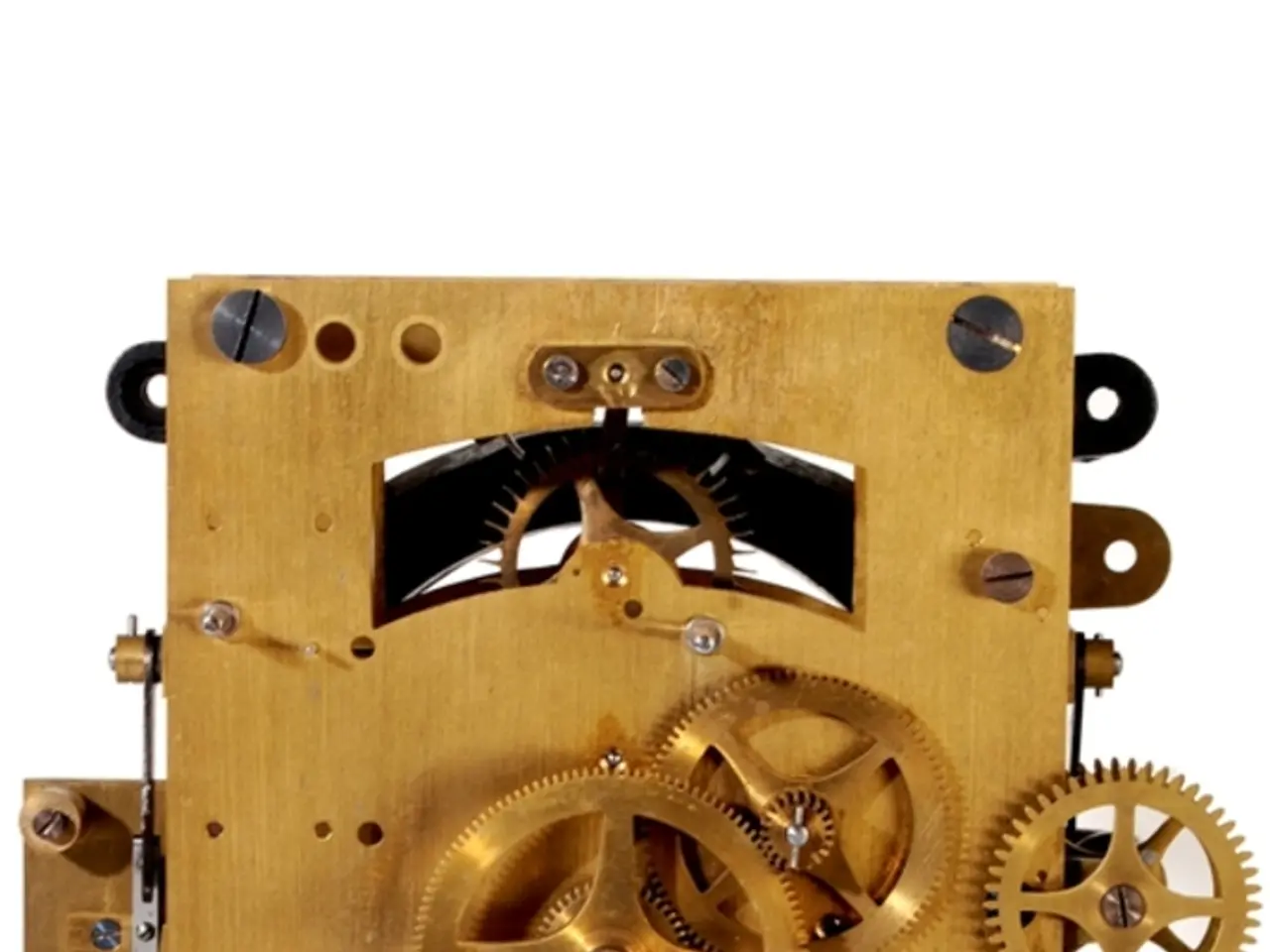

Timely Maintenance and Repairs

Regular maintenance and repairs are essential for the smooth operation of industrial equipment and machinery. Computerized Maintenance Management Systems (CMMS) integrated with IoT-enabled sensors can schedule preventive maintenance based on real-time asset condition, predicting failures before they occur. This not only improves equipment availability and performance but also minimizes costly downtime.

Leveraging Data and Continuous Improvement

Manufacturing Execution Systems (MES), IoT sensors, and analytics platforms provide real-time insights into equipment efficiency, energy consumption, and production bottlenecks. Data-driven decision-making enables predictive maintenance, energy optimization, and targeted process improvements on a continuous basis.

The Importance of Specialist Repair Firms

In cases like industrial tank repair, specialist repair firms offer the expertise and equipment needed to ensure quick and efficient repairs. Their services can help extend the lifespan of machinery, reducing the need for costly replacements.

The Impact of Efficiency on Profit Margins

Efficiency in industry directly affects profit margins. Inefficient processes lead to higher overheads, reducing revenue. Regular maintenance and repairs can help ensure that equipment and machinery operate at optimal levels, reducing the need for costly repairs or replacements.

Training and Documentation

The new workflow should be clearly written out and the person using it should be trained to ensure maximum efficiency. Neglected machinery is more likely to cause accidents, leading to immediate downtime and negative impact on staff morale.

The Long-term Efficacy of Automation

Automation in industry can maintain a constant level of efficacy over the long term, as machines do not require regular breaks or praise. This consistency can help improve the accuracy of the production or manufacturing process, reducing the risk of errors and mistakes.

In conclusion, improving industrial efficiency is best approached by combining proven process improvement methods to refine workflows, strategically applying automation to reduce manual interventions, ensuring preventive and predictive maintenance minimizes downtime, and grounding decisions in real-time data and analytics for sustained enhancement.

- In the context of industry, boosting efficiency through strategies like adopting Lean, Six Sigma, or PDCA frameworks, employing automation, and leveraging data can lead to reduced labor costs, minimized human error, improved equipment availability, and better profit margins.

- Regular maintenance, repairs, and utilization of Computerized Maintenance Management Systems (CMMS) can help extend the lifespan of machinery, prevent costly downtime, and optimize equipment performance, contributing to a more efficient and profitable industrial environment.